Valves and controls are crucial components in various industries, governing the flow and regulation of liquids and gases with precision. Mastering the art of valve control is essential for ensuring the efficient operation of systems in industrial, institutional, and government settings. Valworx stands out as an esteemed ISO 9001-certified supplier of actuated valves and controls, offering a wide range of automated valve assemblies designed to meet diverse needs. With a commitment to excellence, Valworx meticulously builds, tests, and ships these assemblies promptly to provide timely solutions for customers in the markets they serve.

Motorized butterfly valve for remote control

Benefits of Automated Valve Assemblies

Automated valve assemblies offer increased efficiency in industrial processes by streamlining control operations. With Valworx’s range of actuated valves and controls, businesses can experience seamless automation that enhances productivity and reduces labor costs. These assemblies are designed to operate reliably under varying conditions, providing consistent performance over time.

One of the key advantages of utilizing automated valve assemblies is the enhanced safety they offer in critical environments. By automating valve control processes, operators can minimize human error and reduce the risk of accidents or leaks. Valworx’s ISO 9001-certified products ensure compliance with stringent quality standards, further bolstering the safety features of these assemblies.

In addition to operational efficiency and safety benefits, automated valve assemblies contribute to overall cost savings for organizations. The ability to control valves remotely and monitor performance in real-time optimizes resource allocation and minimizes downtime. Valworx’s prompt build, test, and shipping processes enable quick implementation and integration of these assemblies, maximizing return on investment for businesses.

Valve Control Best Practices

When it comes to effectively managing valve control systems, there are several key practices to keep in mind.

Proper maintenance is essential to ensure the longevity and optimal performance of valves and controls. Regular inspections and servicing can help identify potential issues before they escalate, reducing the risk of costly downtime.

Additionally, understanding the specific requirements of each valve and control component is crucial. Proper training and familiarization with the system can empower operators to make informed decisions and operate the system efficiently.

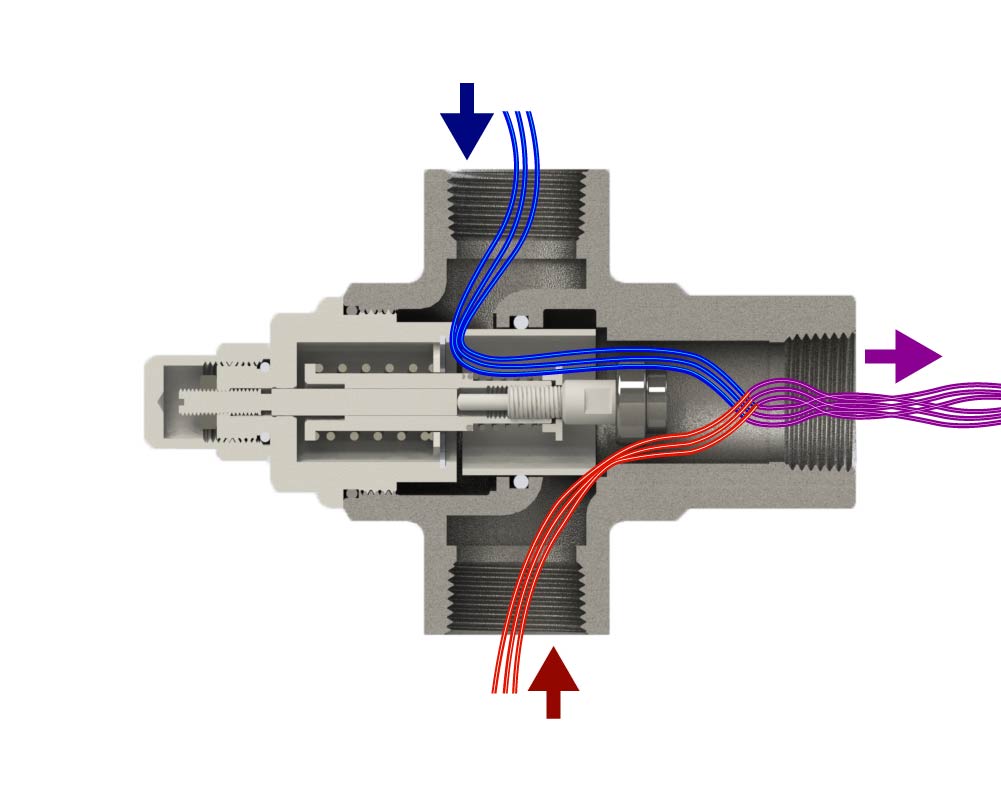

Choosing the Right Valve for Your Application

When selecting a valve for your specific application, it is crucial to consider factors such as the type of fluid being controlled, the operating pressure and temperature, as well as the desired flow rate. Valworx offers a wide range of valves designed to meet various requirements, ensuring that you find the perfect fit for your needs.

One key consideration is the material of the valve, as different materials offer varying levels of durability and compatibility with specific fluids. Valworx provides valves constructed from high-quality materials, such as stainless steel and brass, to guarantee reliability and longevity in diverse operating conditions.

Additionally, understanding the operating conditions and environment of your application is essential in choosing the right valve. Valworx’s expert team can assist you in selecting the ideal valve type, whether it be ball valves, butterfly valves, or solenoid valves, to ensure optimal performance and efficiency in your system.