Welcome to the comprehensive guide on IGBT modules! These vital components play a crucial role in power electronics, offering a combination of the high-speed switching capability of power MOSFETs with the high power handling capability of bipolar transistors. IGBT modules are commonly used in a wide range of applications, from motor drives and renewable energy systems to industrial equipment and electric vehicles.

By understanding the inner workings and applications of IGBT modules, you can harness their immense power effectively. Stay tuned as we delve deeper into the world of IGBT modules, exploring their design, functionality, and the key factors to consider when incorporating them into your projects. Let’s unlock the potential of these innovative devices and unleash their power in your next endeavor.

Applications of IGBT Modules

In various industries such as renewable energy, electric vehicles, and industrial automation, IGBT modules play a crucial role in power conversion applications. These modules are widely used in renewable energy systems to efficiently convert energy from sources like solar panels and wind turbines into usable electricity.

In the automotive sector, IGBT modules are essential components in electric vehicles (EVs) to control the power flow between the battery, motor, and other electronic systems. Their high power handling capabilities and fast switching speeds make them ideal for enhancing the efficiency and performance of EV drivetrains.

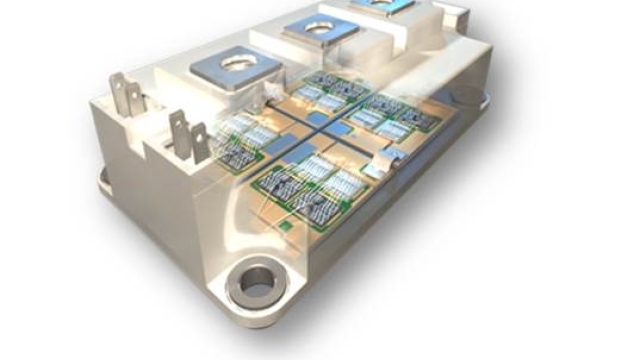

IGBT Module

Moreover, in industrial automation processes, IGBT modules are employed in motor drives, power supplies, and welding equipment to regulate voltage and current levels. This enables precise control over machinery operations, leading to improved productivity and energy efficiency in manufacturing facilities.

Advantages of Using IGBT Modules

One significant advantage of using IGBT modules is their high efficiency, which helps in reducing energy consumption and minimizing heat generation. This efficiency is particularly beneficial in applications where power management is critical, leading to cost savings in the long run.

Another key advantage of IGBT modules is their robustness and reliability, making them ideal for use in demanding environments. With their ability to handle high voltages and currents, these modules offer a durable solution that can withstand harsh conditions without compromising performance.

Furthermore, IGBT modules provide precise control over power flow, allowing for efficient voltage and current regulation. This level of control is essential in various applications such as motor drives, renewable energy systems, and industrial equipment where precise power management is crucial for optimal operation.

Future Trends in IGBT Technology

In the rapidly evolving landscape of power electronics, IGBT modules continue to undergo significant advancements to meet the growing demand for energy-efficient solutions. One prominent trend is the development of IGBT modules with higher voltage and current ratings, enabling them to handle greater power densities while maintaining optimal performance.

Another key trend in IGBT technology is the integration of advanced thermal management solutions to address the challenge of heat dissipation. By incorporating innovative cooling methods such as liquid cooling or enhanced heat sinks, manufacturers are able to enhance the reliability and longevity of IGBT modules, especially in high-power applications where thermal management is crucial.

Furthermore, the enhancement of IGBT module packaging technologies is a prominent trend that aims to reduce electrical losses and improve overall efficiency. By utilizing materials with superior thermal conductivity and optimizing the design of module housings, engineers can minimize parasitic elements and achieve higher switching frequencies, resulting in more efficient power conversion processes.